Industry news|2022-06-01| admin

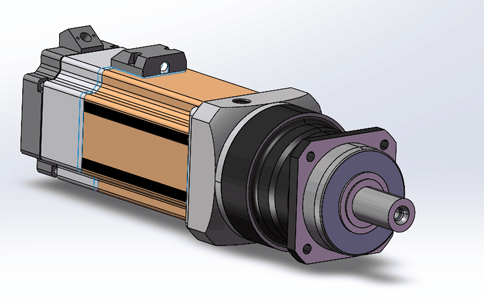

The combination of servo motor and gearbox is often seen in transmission mechanisms. The high torque and high precision of the gearbox is very suitable for the motor. The servo motor needs a high-speed gearbox, and the general gearbox cannot meet the needs of the servo motor. The characteristics of the planetary gearbox are very suitable for use with servo motors. So, how to match the servo motor and gearbox? What are the parameters that need attention? Let's find out together.

1. Calculation of the output torque of the gearbox

The output torque of the gearbox is the required torque calculated by the transmission mechanism. The purpose of selecting the gearbox is to save costs under the condition of torque guarantee. NEUGART planetary gearbox has a variety of models, and the application scenarios of the gearbox are also extensive. There will be a variety of suitable gearboxs for different scenarios. You can choose the appropriate gearbox according to your own needs or budget. Secondly, the application of the gearbox in the mechanical structure has many advantages, such as reducing inertia, reducing the impact of the transmission mechanism on the servo motor, self-locking transmission mechanism, high load capacity and so on. Of course, its core value is to increase torque. So when you confirm the torque required by your transmission mechanism, then compare the torque of the servo motor you selected, and then the ratio of these two torques is the reduction ratio of the torque of the gearbox you want to choose. In the selection process The choice of medium torque will be a little more than actually needed, so the transmission ratio should be selected slightly larger. So in this process, two parameters are very important, namely the final torque you need and the rated torque of the servo motor. Only by knowing these two parameters can you confirm the reduction ratio of the gear motor you choose.

2. Calculation of the operating speed of the mechanism

For the maximum speed of the transmission mechanism, this needs to be confirmed in advance, because this parameter involves the selection of the reduction ratio of the gearbox. When we choose the reduction ratio, it does not mean that the reduction ratio can be increased infinitely, because the reduction The larger the ratio, although the torque will be larger, but it also means that the output speed will be reduced, which also leads to a reduction in the operating speed of the entire transmission mechanism.

Therefore, between torque and speed, we need to do a balance. On the premise of satisfying the transmission speed of the mechanical mechanism, it is a reasonable choice to increase the reduction ratio as much as possible to increase the transmission torque. Of course, the transmission speed of a transmission mechanism is not completely determined by the gearbox, so when we do the structural design, we need to consider it comprehensively, but the size of the reduction ratio is also a determining factor, which needs our attention.

3. Selection of the transmission accuracy of the gearbox

The transmission accuracy of the gearbox depends on the accuracy requirements of the transmission mechanism, and the accuracy of the gearbox can be matched according to its own needs.

4. Selection of the installation method of the transmission mechanism

For the selection of the gearbox, in addition to the above parameter selection, it is also necessary to choose the type and installation method of the gearbox, whether it is a flange type gearbox or a shaft output gearbox, whether there are keys on the shaft and other installation methods.

5. Determine the size of the gearbox shaft

In some special cases, it is necessary to customize the input or output shaft of the gearbox. This can be confirmed when the gearbox is selected. According to the needs of its own transmission mechanism, the parameters of the technical motor are provided to us. NCP professional selection The type software can provide the appropriate gearbox model and size, and the appropriate gearbox can be selected according to the recommended gearbox model of the system.

The above is the relevant knowledge about how to match the servo motor and the gearbox. The servo motor chooses the planetary gearbox because the input speed of the planetary gearbox can well meet the needs of the motor. In the process of selecting the gearbox, you need to pay attention to deceleration. The accuracy, torque, speed of the machine, the size and installation method of the gearbox, etc. are basically determined before the selection. Moreover, we have NCP selection software, covering common motor models in the market. You only need to provide the motor parameters and the required speed ratio, torque and other parameters of the gearbox to match the suitable gearbox model, and have the gearbox and motor running. dynamic data drawings.